Most companies underestimate the importance of having tolerances in 3D printing for projects. It refers to how close a project stays to the dimension in the original design. Even a tiny deviation in the tolerance leads to inaccurate fit, quality, and functioning of the 3D printing prototyp (3D druck prototyp). Let’s understand what this really means and how it impacts the finished component.

What Exactly Are Tolerances in 3D Printing?

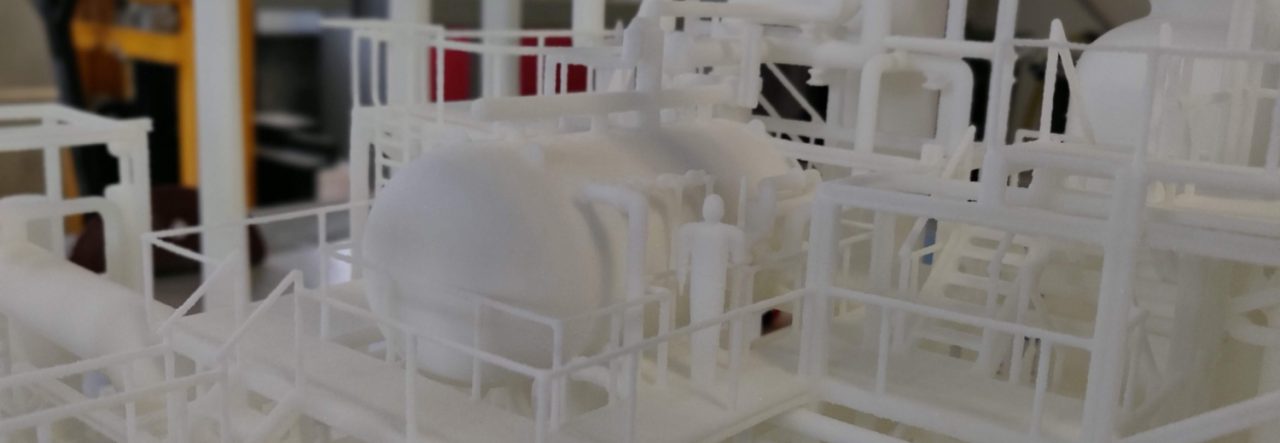

In 3D printing, tolerance decides the overall look of the printing. Let’s first understand “What is Tolerance?”. Tolerance sets the boundaries for dimensional accuracy. It anticipates that the dimensions will match the printed products. A tight tolerance means you’ll get the exact print, while a broader tolerance means inaccurate print is possible.

Getting an accurate print depends on tight tolerance. However, other minor issues can surface even within tight tolerance. Sometimes, minor gaps and unwelcoming changes can happen. Attention to detail is required for a perfect 3D print illustrative model (anschauungsmodell).

How Less Than 0.5% Tolerance Affects Your Project

0.5% tolerance plays a crucial role in determining the quality of the print. Whenever a 3D has a tolerance of 0.5%, this means that any variation stays below 0.5 mm in a 100 mm component. This precision matters for projects where exact fits are necessary.

To achieve high-quality printing, you must review the tolerance capabilities. It’s essential to review the design machines throughout the printing process to produce superior outcomes. A slight variation may not seem so significant, but it can make a big difference.

Why tolerances matter for functional parts

High quality depends on the machine’s capability to endure mechanical strain or pressure. More tolerance means fewer chances of committing mistakes. Little dimensional shifts result in poor fittings. As a result, 3D printing is misaligned and loses its alignment.

Another crucial aspect of 3D printing is the material type. Every material behaves differently during warping, shrinking, or cooling. Which in turn influences the ultimate dimension. Many printing services specialize in advanced processes to keep these factors under control.

The best method to get the perfect 3D print is to try, test, and measure the effect of each factor. Give accurate details to manufacturers regarding the desired result to get the best results.

About Additive Elements:

Additive Elements specializes in advanced 3D printing art (3D druck kunst) solutions. With years of experience in the industry, the company provides high-quality, sustainable manufacturing and 100% material recycling.

For more information about 3D printing services, visit https://www.additive-elements.de/

Original Source: https://bit.ly/3NZ5SrL

Tag: anschauungsmodell

Reasons for the Rising Vogue of 3D Printing

3D printing is not anything new to the world. It has been years since we were introduced to this technology. It’s intriguing how 3D printing has been taking over the world with its extraordinary applications and benefits. Usually, 3D printing is done using a digital 3D model. The illustrative model (anschauungsmodell) helps create prototypes quite easily. Here are several advantages of 3D printing.

Rapid Prototyping:

Prototypes are essential for creating main products, structures, and designs. However, manual prototyping was kicked away decades ago. The introduction of technology in this matter turned out to be more efficient. After several improvements and modifications in the technology, the world received the 3D printing aid.

3D printing is a process used to forge a product or object using its 3D model. It includes laying multiple layers, one over another, step by step, to create the complete prototype. Since manual procedures involved more time and effort, 3D eliminated all these concerns. The process is faster and more efficient.

Minimum Waste:

3D printing is not just limited to creating prototypes. Instead, the process is widely used in other fields and disciplines currently. For instance, a 3D printing prototype (3D druck prototyp) is useful in architecture, engineering, product manufacturing, and similar other fields.

3D printing is excellent in many ways. One of the advantages of this technology and technique is less or no waste generation. The layering is done strictly according to the 3D model. Therefore, there are no or lesser errors in the process.

Cost Efficient:

Another excellent reason to prefer 3D printing is cost efficiency. Manual prototyping, manufacturing, etc., requires manual effort, materials, and techniques. Still, there are chances of errors. As a result, even after so many contributions, one still has to bear unnecessary expenses.

However, 3D printing laid the path to cost efficiency. It requires fewer manual contributions. Along with this, the time-saving process allows saving costs as well. Therefore, this is going to be a solution that will beat the time. 3D printing can be timeless with consistent introductions in the technology and improvement.

About Additive Elements:

Additive Elements knows the worth of 3D printing housing (3D druck gehäuse) and everything related. Therefore, the company is a leading additive manufacturer in the field. It uses its own 3D printing process called thermal liquid curing (TLC). Additive Elements also bring various materials, like AE21 and Ae12+. So, check out this service now.

Find all the details at https://www.additive-elements.de/

Original Source: https://bit.ly/4d2JE2K