Additive Elements has many years of experience providing 3D printing services according to various needs with accuracy and quality products. This company focuses on turning ideas into reality using advanced technology. This company is committed to continuously researching and updating its approach to provide high-quality 3D printing (3D druck online) services.

This company delivers solutions according to the client’s requirements with great attention to detail and quality material selection. Choosing their services is helpful to businesses and individuals in creating functional prototypes and models efficiently. Their effort and dedication to quality ensure that every part is designed accurately.

Thermal Liquid Curing (TLC) Process

Additive Elements has developed its unique 3D printing (3D drucken lassen) technology, known as Thermal Liquid Curing (TLC). This technology helps set a new standard for creating components with excellent mechanical properties. This technology eliminates the difficulties in the production of parts with top-tier quality.

The best advantage of using this technology is that it makes the process highly efficient and offers superior results at an affordable price. This technology ensures that every component can be prepared with care and precision. With TLC, this company has achieved advancements in 3D printing to provide solutions that meet high-quality and cost-efficient goals.

Binder-Jetting Technology

The use of binder-jetting technology by Additive Elements takes a significant step forward in 3D printing services. With the help of this technology, it is possible to create dense plastic parts. This technology focuses on precision and helps make durable components with various applications.

This company’s dedication to advancing the capabilities of 3D printing service (3D print service) with the help of binder jetting ensures that clients receive parts that meet their exact specifications and requirements. This approach improves the components’ quality and helps make prototypes for industries that require precise and reliable plastic components.

Sustainable 3D Printing Practices

Additive Elements is committed to sustainability in 3D printing to achieve a 100% recycling rate for unused powder. This eco-friendly approach helps reduce material waste and also contributes to preserving the environment. Following this, this company minimizes material consumption to ensure that resources are used responsibly while making high-quality components.

This dedication to sustainability shows their effort to balance innovation with environmental responsibility. This company’s unique approach reflects a forward-thinking mindset with every step taken by understanding the impact. This ensures that this company follows both quality and responsible production practices. This company also offers post-treatment options like glass beading, chemical straightening, and threaded insert assembly services.

To get more details, visit https://www.additive-elements.de/

Original Source: https://bit.ly/3EsSDhj

Author: Additive Elements

City Development Authorities Using 3D Printing Services for Planning and Development

Planning is the stepping stone of every process and endeavor. Without efficient planning, it is impossible to execute and bring an idea to life. Therefore, planning requires more emphasis than ever. For instance, city development authorities create a plan & prototype and then kick start the process. Prototyping is easier with the help of a 3D printing service provider (3D druck dienstleister). Here’s how authorities can utilize this facility.

Apartments Under a Plan:

Authorities often introduce ideas to provide suitable accommodation to citizens. Apartments and structures are developed for this. However, before any construction process begins, engineers, planners, and managers discuss the idea.

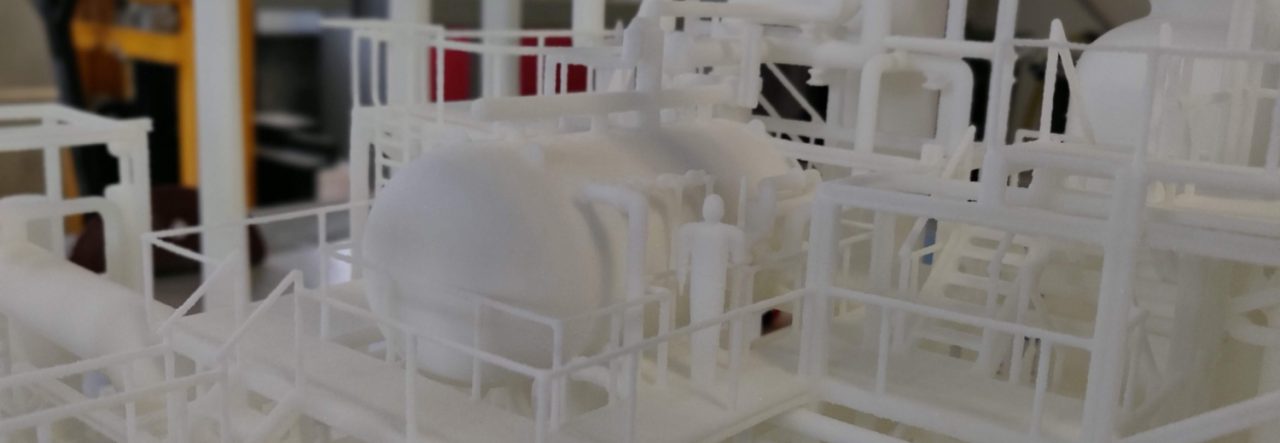

They utilize 3D printed models to share their thoughts and development plans. These 3D models provide a clear image of the final construction that lowers doubts. Moreover, a 3D model is easier to understand and analyze. This way, errors in the design are identified and addressed right away.

Developing Commercial Areas:

It is crucial to transform commercial areas to attract the masses and remain updated according to architectural trends. City development authorities can use a 3D illustrative model (anschauungsmodell) in such cases as well.

3D models help understand the design and planning better. For example, it is not always crucial to demolish the entire area and reconstruct it. Some elements can be restored and are ready to fit into the new plan. 3D modeling will help construction contractors and engineers understand it better. Therefore, authorities rely on these 3D-printed models more in such cases.

Landscape Constructions:

Authorities try to turn the city into an appealing space. Common landscapes in central parks, roadsides, etc., can be a great addition to the environment. Landscaping designs can involve natural and artificial elements. It may depend on ideas shared by the experts.

City councils and development authorities can discuss projects better with the help of 3D illustrative models. The designers can share the design and the final image of the landscape using these models. This way, the authorities can understand and question the areas. 3D printing service providers can help designers in such cases.

About Additive Elements:

Additive Elements is a reliable large format 3D printing (Großformat 3D druck) service. It brings AE12+ and AE21, the printing materials known for their resilience, performance, and results. These printing materials are perfect for construction modeling and more. Authorities can utilize these services and get excellent aid to make rational decisions.

Check all the details at https://www.additive-elements.de/

Original Source: https://bit.ly/4axmdyo

Industries Appreciating Additive Elements and Its 3D Printing Services

Technological evolution is a way to address obstacles, concerns, and challenges. Industrial development and association of the latest technological solutions introduce simplified procedures and outcomes. For example, developments in 3D printing online (3D druck online) are incredible and prove their worth. 3D printing providers offer technology, materials, and other solutions to improve results.

Additive Elements is an exceptional service in the field with impressive support and record. It has proved itself by assisting industries from automotive, construction, and aeronautics to art and design.

Here’s why it remains an unbeatable service.

Large Format 3D Printing:

3D printing can utilize various materials, including metals, ceramics, polymers, glass, etc. But it had some restrictions. Only small-sized designs can be converted into illustrative models. But printing large formats and designs seemed impractical.

Additive Elements has eliminated the problem with its large format 3D printing (Großformat 3D druck) services to a great extent. Larger formats are not a concern for this service. Designers can get 3D prints of lengths up to 850 mm, which is impressive. Such large formats improve illustrative modeling for architects, landscapers, etc. This way, designing takes an improved form, dumbing down the further procedures.

Materials and Technology:

Thermal Liquid Curing turned out to be a sensational introduction with exemplary results. The 3D printing technology decoded every complication, from distortion & warpage to material wastage. TLC proved to be a sustainable method for 3D printing.

Additive Elements developed the TLC method with enhanced results. Along with the technique, the firm created two upright 3D printing materials. AE12+ and AE21 are among the finest solutions available in the industry. These materials have impressive characteristics and can serve designing and manufacturing fields. These introductions from this firm transformed prevalent 3D printing practices.

The Post-Processing Methods:

3D printing the design is not the end of the process. You are only halfway to the goal. A 3D printing service (3D print service) supports its customers with post-processing services, too. These services improve the outcomes and turn mere 3D prints into visually appealing illustrative models. Therefore, these services play a crucial role in the end, too.

Additive Elements proceeds with the post-processing methods after completing the 3D prints. The process involves compacting and smoothing the surface. Clients can ask to paint the 3D print with any RAL color. The model will be painted after sanding the surface for a cleaner, smoother, and sleeker look. So, get these services now!

Check out more details at https://www.additive-elements.de/

Original source: https://bit.ly/4fL3LDh

Why are Modern 3D Printing Materials and Solutions Better?

Prototyping appeared complex, unclear, and insignificant before makers came up with 3D printing. It facilitated various industries and blurred the boundaries between designs and actual products. It made it easier to understand the details and incorporate them into the manufacturing process. Modern 3D printing prototype (3D druck prototyp) solutions are far better. Here are a few reasons to consider them ahead of other solutions.

Better Materials:

3D printing specialists used metals, nylons, resins, etc., earlier. These products were easy to source and use. However, they carried a series of issues with them. For example, their thickness remained a profound concern. It failed to maintain the level of detail needed in prototyping.

Modern 3D printing materials are better. The best part is their availability in fine powder form. The tiny powder granules melt and take the shape as designed by the expert. As a result, the detailing part takes a positive drift and gives excellent results. It facilitates manufacturers’ understanding of every inch of the designs.

Better Techniques:

Formerly used 3D printing materials were difficult to handle. High distortion and detail-related issues made them more challenging to work with. However, materials were not the only issue. Techniques used to convert these materials into a 3D-printed illustrative model (anschauungsmodell) were also inefficient.

Modern 3D printing technologies are far better. These technologies reduce distortion. Also, the detailing part is no longer a concern. Instead, it is impressive enough to give a face to a design.

The Bottom Line:

You may need the best solutions for 3D printing, whether related to materials or technology. In such cases, you should contact 3D printing services. They evolve materials and technology to improve the results. Their assistance can significantly transform the design and manufacturing procedure.

3D printing services offer incredible assistance to various industries. They contribute to construction, interior design, landscaping, product design, and many other procedures. This way, they simplify the situation for professionals working on a project. For example, an architect can better explain the project details to the civil engineer and his team, along with the client.

About Additive Elements:

Additive Elements is the 3D printing service you need. The company offers 3D printing housing (3D druck gehäuse) solutions to try. The company brings materials like AE21 and AE12+, along with extraordinary thermal liquid curing technology. You can trust its products, solutions, and services. So, contact this expert company now!

Check out more at https://www.additive-elements.de/

Original Source: https://bit.ly/4fcZc4F

Additive Elements Introduces AE 21 Materials for 3D Printing in Housing

AE 21 materials are engineered to meet the unique demands of 3D printing technology. Additive Elements is a trusted 3D print service that introduces its AE21 materials. It is designed for 3D printing in housing, prototype, and construction. The company promises to revolutionize the way building components are constructed.

Sustainable and Efficient Construction

One of the critical benefits of Additive Elements’ AE 21 is its sustainability. This material is made from eco-friendly components, reducing the carbon footprint during construction. The company uses advanced 3D printing methods, minimizing waste. It builds structures layer-by-layer, ensuring the necessary amount of material is used.

In addition to sustainability, Additive Elements offer significant cost savings. Traditional construction methods involve expensive labor, materials, and logistics. With the company’s 3D printing, you can streamline the building process, resulting in fast construction times and lower overall project costs.

Versatility for Housing Components

Additive Elements’ AE 21 is not limited to full-scale homes. It can also create individual housing components, including foundations, walls, and structural supports. These components are engineered for easy integration with other materials. They make them ideal for both new builds and renovations. The materials are compatible with various 3D printing online (3D druck online)systems, making them accessible for builders, architects and contractors. This flexibility is essential as the construction industry continues to explore the potential of manufacturing.

Addressing Housing Challenges

The global housing crisis is a significant issue. Additive Elements’ AE 21 enables the rapid construction of high-quality, affordable housing. It reduces costs and construction times, opening up new opportunities for affordable housing projects.

Additive Elements announces its AE21 in the market. With the growing demand for housing, the company’s materials allow the construction industry to build an efficient footprint. The company plays a crucial role in shaping the future of housing construction.

Looking to the Future

Additive Elements plans to expand its line of AE 21 materials to include further formulations for different construction needs. The company is committed to continuing innovation in the field of 3D printing. It supports the global push for sustainable, affordable and efficient housing with advanced printing materials.So, get 3D printed (3D drucken Lassen) systems today.

Additive Elements’ AE21 is now available for commercial applications. Its experienced 3D printing experts work with construction partners to integrate this technology into their projects.

Additive Elements is a leader in standard 3D printing materials. The company specializes in developing innovative products that meet the industry’s needs. Focusing on sustainability, efficiency, and technology, it is committed to driving the future of additive manufacturing.

Get more information at https://www.additive-elements.de/

Original Source: https://bit.ly/4gf0bCJ

Large Format 3D Printing Made Less Complicated with Additive Elements

3D printing procedures followed by expert companies differ at certain levels. Companies use dissimilar materials and methods for prototyping, modeling, etc. 3D printing bridges the gap between designers and manufacturers. Therefore, manufacturers get 3D printed (3D drucken lassen) designs before starting any project.

Additive Elements is one of the remarkable services in the industry. The company has introduced clients and customers to brilliant 3D printing methods and materials. It strives to make large-format 3D printing less complicated.

Introducing Materials:

3D printing is prominent in product design, architecture, education, art, manufacturing, advertising, aerospace, etc. It gives life to a 2D design and simplifies further understanding, manufacturing, assessing, etc. 3D printing depends on the materials and methods used. The use of material determines its finish and attention to detail. 3D printing requires the right materials to ensure excellent results.

Additive Elements handles this part well. The company brings excellent material options that clarify 3D printing online (3D druck online). For instance, the AE21 material is perfect for functional components. It is an ideal option for electrical appliances, molding, machine parts, movable parts, etc. Similarly, AE12+ suits view model requirements. It is an excellent solution for landscapes and product models.

Technology Used:

TLC technology is a revolutionary introduction to the 3D printing industry. This technology relieved large-format 3D printing. It includes all the design details in the printed prototypes and final products. Also, it reduces wastage and distortion possibilities during the process.

Additive Elements transformed the process with its thermal liquid curing technology. It is the advanced version of the binder jetting method. This method involves the complete dissolving of material grains and granules. The final product printed using this technology is finished and ready for further processing. Therefore, it is among the most prominent methods in the industry.

Cost Effectiveness:

The introduced materials and thermal liquid curing technology eased large format 3D printing (großformat 3D druck) to a great extent. This intense transformation in the process benefitted designers and manufacturers in many ways. For instance, it is now possible to get 3D prints of large-format designs and files without worrying about distortion and cracks.

Additive Elements has always been excellent in its field. The company introduces solutions that even deliver cost benefits to users. TLC and 3D printing materials result in less waste. Moreover, the leftover materials are reusable. As a result, the cost associated with 3D printing drops significantly.

Check out more at https://www.additive-elements.de/

Original Source: https://bit.ly/3UYycyh

Additive Elements: Providing The Most Outstanding 3D Printing Service

If you are searching for a 3D printing service (3D druck service), you should work with a company that offers the most seamless experience. Additive Elements is a company that you can work with. It provides cost-effective solutions. This company is sustainable and offers solutions with utmost precision and accuracy. So, when you require assistance in the additive manufacturing industry, you should choose it. Let’s discuss more.

Innovative Technology

Additive Elements relies on a self-developed 3D printing process. This process is TLC, which stands for Thermal Liquid Curing. It helps produce quality components. The mechanical properties are also outstanding. These solutions are available at reasonable prices. So, with the help of binder jetting technology, the company can easily produce dense plastic parts. Therefore, you can get a variety of solutions with this one-of-a-kind 3D printing technology. This company focuses on innovation and prioritizes the needs of clients.

How the TLC Process Benefits

The TLC process at Additive Elements offers a high level of detail. Hence, it is favorable for everyone. The powder is recycled completely, which makes it a sustainable process. The components are up to 850 mm edge length. It is a patent process, which is highly beneficial for saving energy resources. This company has worked with several customers.

Post-Processing Methods

At Additive Elements, the company provides a wide range of post-treatment options. You can find various choices such as chemical straightening, glass bead blasting, painting, finishing, and more. These steps can be combined according to your preferences. When the material is sanded and drilled, the application will be the same for you.

Customer Testimonials

If you are still confused about whether you should get 3D print service from Additive Elements or not, you can check the customer testimonials on the website. The customer testimonials will help you understand how this company always surpasses expectations for customers and partners. If you have any queries, you can fill out the form on the website by sharing basic details like name, email, company theme, etc. The company will reach out to you to answer your queries.

Three Easy Steps

The process has only three easy steps. The first step is inquiry, where you can contact the company and send your data. You can choose the best material with its guidance. Once the components are manufactured, they will be shipped to you safely. If you want to work with a 3D printing service provider(3D druck dienstleister), look no further than Additive Elements. This company will never disappoint you.

To get more details, visit https://www.additive-elements.de/

Original Source: https://bit.ly/3UTah3i

Understanding the 3D Printing Process

3D printing procedures followed by expert companies differ at certain levels. Companies use dissimilar materials and methods for prototyping, modeling, etc. 3D printing bridges the gap between designers and manufacturers. Therefore, manufacturers get 3D printed (3D drucken lassen) designs before starting any project.

Additive Elements is one of the remarkable services in the industry. The company has introduced clients and customers to brilliant 3D printing methods and materials. It strives to make large-format 3D printing less complicated.

Introducing Materials:

3D printing is prominent in product design, architecture, education, art, manufacturing, advertising, aerospace, etc. It gives life to a 2D design and simplifies further understanding, manufacturing, assessing, etc. 3D printing depends on the materials and methods used. The use of material determines its finish and attention to detail. 3D printing requires the right materials to ensure excellent results.

Additive Elements handles this part well. The company brings excellent material options that clarify 3D printing online (3D druck online). For instance, the AE21 material is perfect for functional components. It is an ideal option for electrical appliances, molding, machine parts, movable parts, etc. Similarly, AE12+ suits view model requirements. It is an excellent solution for landscapes and product models.

Technology Used:

TLC technology is a revolutionary introduction to the 3D printing industry. This technology relieved large-format 3D printing. It includes all the design details in the printed prototypes and final products. Also, it reduces wastage and distortion possibilities during the process.

Additive Elements transformed the process with its thermal liquid curing technology. It is the advanced version of the binder jetting method. This method involves the complete dissolving of material grains and granules. The final product printed using this technology is finished and ready for further processing. Therefore, it is among the most prominent methods in the industry.

Cost Effectiveness:

The introduced materials and thermal liquid curing technology eased large format 3D printing (großformat 3D druck) to a great extent. This intense transformation in the process benefitted designers and manufacturers in many ways. For instance, it is now possible to get 3D prints of large-format designs and files without worrying about distortion and cracks.

Additive Elements has always been excellent in its field. The company introduces solutions that even deliver cost benefits to users. TLC and 3D printing materials result in less waste. Moreover, the leftover materials are reusable. As a result, the cost associated with 3D printing drops significantly.

Check out more at https://www.additive-elements.de/

Original Source: https://bit.ly/3NWq2Tn

Understanding 3D Printing Tolerances: What <0.5% Means for Your Project

Most companies underestimate the importance of having tolerances in 3D printing for projects. It refers to how close a project stays to the dimension in the original design. Even a tiny deviation in the tolerance leads to inaccurate fit, quality, and functioning of the 3D printing prototyp (3D druck prototyp). Let’s understand what this really means and how it impacts the finished component.

What Exactly Are Tolerances in 3D Printing?

In 3D printing, tolerance decides the overall look of the printing. Let’s first understand “What is Tolerance?”. Tolerance sets the boundaries for dimensional accuracy. It anticipates that the dimensions will match the printed products. A tight tolerance means you’ll get the exact print, while a broader tolerance means inaccurate print is possible.

Getting an accurate print depends on tight tolerance. However, other minor issues can surface even within tight tolerance. Sometimes, minor gaps and unwelcoming changes can happen. Attention to detail is required for a perfect 3D print illustrative model (anschauungsmodell).

How Less Than 0.5% Tolerance Affects Your Project

0.5% tolerance plays a crucial role in determining the quality of the print. Whenever a 3D has a tolerance of 0.5%, this means that any variation stays below 0.5 mm in a 100 mm component. This precision matters for projects where exact fits are necessary.

To achieve high-quality printing, you must review the tolerance capabilities. It’s essential to review the design machines throughout the printing process to produce superior outcomes. A slight variation may not seem so significant, but it can make a big difference.

Why tolerances matter for functional parts

High quality depends on the machine’s capability to endure mechanical strain or pressure. More tolerance means fewer chances of committing mistakes. Little dimensional shifts result in poor fittings. As a result, 3D printing is misaligned and loses its alignment.

Another crucial aspect of 3D printing is the material type. Every material behaves differently during warping, shrinking, or cooling. Which in turn influences the ultimate dimension. Many printing services specialize in advanced processes to keep these factors under control.

The best method to get the perfect 3D print is to try, test, and measure the effect of each factor. Give accurate details to manufacturers regarding the desired result to get the best results.

About Additive Elements:

Additive Elements specializes in advanced 3D printing art (3D druck kunst) solutions. With years of experience in the industry, the company provides high-quality, sustainable manufacturing and 100% material recycling.

For more information about 3D printing services, visit https://www.additive-elements.de/

Original Source: https://bit.ly/3NZ5SrL

Additive Elements: Your Perfect Partner For 3D Printing Service

Are you searching for cost-effective 3D printing online (3D druck online) solutions? If so, you should work with a trusted name in the industry like Additive Elements. This company offers a powder-based online 3D printing service. You can get these solutions for up to 850 mm in length.

Moreover, this company has been focusing on sustainability. It recycles around 100%. This innovation has been made completely in Germany. This company is one of the most renowned service providers in this field. So, when it comes to additive manufacturing, all you need to do is contact Additive Elements. This company prioritizes efficiency and quality over everything else.

If you choose Additive Elements, you will always be stunned by the results. Let’s discuss more.

Self-developed 3D printing process

Additive Elements has developed a 3D printing process TLC (Thermal Liquid Curing). This process helps ensure they only produce the most premium quality components. The mechanical properties are also excellent and there is low war page too. The best part is the price range. The 3D printing service (3D druck service) is available at reasonable prices. This unique process helps produce dense plastic parts with the help of binder jetting technology. This is happening for the first time.

Protecting the environment

Additive Elements is highly careful towards the environment and wishes to protect it. The unique process helps achieve an almost 100% powder recycling rate. The company ensures to keep the environment safe while completing the production of functional components. This unique process has been patented. It helps reduce resource and energy consumption.

Getting the finished component

The first thing you need to do is check out the contact form on the website of Additive Elements. You can also share your CAD data through email. After this, the company will connect and guide you in choosing the perfect material. It will also work on optimizing the data for 3D printing. The last step would be manufacturing and shipping. The team of Additive Elements will manufacture the components and ship them if you need them.

Several customers and partners

Additive Elements has worked with a wide range of customers and partners. Some of them are the most trusted companies. You can easily rely on the experience of additive developments and work with them for your needs. If you wish to get 3D printed (3D drucken lassen) solutions, check out the website of Additive Elements today. This company will offer excellent results.

To get more details, visit https://www.additive-elements.de/

Original Source: https://bit.ly/3X3oriq